dna decontamination autoclave|UV irradiation and autoclave treatment for elimination of : factory DNA decontamination reagents use three different molecular prin-ciples for destruction or . Location: Sugar Land

{plog:ftitle_list}

Lame de terrasse en pin préservé classe 4 par autoclave vert comportant une face rainurée et une face lisse. Véritable incontournable, Le Pin est la référence en lames de terrasse bois pour un projet de qualité à prix maitrisé.

This study evaluates the decontamination efficiency of ten different cleaning strategies: ethanol, UV radiation, ethanol in combination with UV radiation, fresh and stored household bleach, DAX Ytdesinfektion Plus, Rely+On TM Virkon ®, Trigene ®, DNA Remover ®, and sodium .DNA decontamination reagents use three different molecular prin-ciples for destruction or . Here, we performed a step-by-step evaluation of current DNA decontamination methods and developed an effective procedure for assessing the presence of decontaminating DNA via PCR analysis. Performing targeted environmental surveillance by sampling, which reached optimal performance over 2 weeks, and the decontamination process had been .

distributor outlets autoclavable

Experimental design. Different experiments were designed to assess DNA sterilization methods such as decontamination using 10% bleach solution, ethanol solution, and DNA-ExitusPlus IF (PanReac AppliChem, Germany) in two different DNA laboratory settings, i.e., low template DNA lab and reference DNA lab (abbreviated as CW and DB respectively) as . In addition, the DNA decontamination methods identified by Ballantyne et al. [17], namely, a 1% hypochlorite solution and a 5% Virkon solution, were assessed for their ability to clean and eradicate DNA from squirrel hair and fiberglass fingerprint brushes. DNA profiling results from surfaces contacted by cleaned and uncleaned brushes were .

Decontamination is a more general term referring to ridding an item of contamination [8]. For killing of bacteria or yeast, sterilization and decontamination can be considered the same thing. In forensic biology laboratories, the contaminant of concern is human DNA either in its extracted or cellular form. While there are many methods available forExitusPlus™ and conventional DNA decontamination reagents. 200 ng of CCC plasmid DNA each, were treated with 5 μl of the indicated reagent for 3 or 10 min respectively. . equipment that fit into the autoclave. Under the standard autoclaving conditions, DNA molecules are believed to be degraded into very small fragments. But PCR analysis . The development of DNA decontamination methods was performed with DNA fragments used only for this purpose. . Kahn R (2010) UV irradiation and autoclave treatment for elimination of contaminating DNA from laboratory consumables. Forensic Sci Int Genetics 4: 89–94. View Article Google Scholar 16. .

and equipment that fit into the autoclave. Decontamination of labo-ratory benches or larger equipment is impossible. Efficient degradation of DNA molecules by DNA-ExitusPlus™ . ure 2) for DNA decontamination cause irreversible corrosion and damages to many of the metal surfaces. For DNA-ExitusPlus™ (D+) no damage of Examples of Effluent Decontamination Systems. There are three acceptable methods for decontaminating the effluent from an autoclave. Internal HEPA Filter. This method utilizes a 0.2-micron, ultra high-efficiency HEPA filter located within the autoclave chamber.

The corrosive potential of selected conventional DNA decontamination reagents in comparison with DNA-ExitusPlus.Aliquots of each listed reagent were applied to metal plates that are typically used .We examined the ability of hydrogen peroxide plasma (HPP) to remove DNA contamination, to evaluate whether it is a suitable forensic-grade treatment under ISO 18385. HPP treatment was compared to ethylene-oxide gas (EOG) treatment, which is required by ISO 18385. For the evaluation, commercial contr .Decontamination—Any process for removing and/or killing microorganisms. The same term is also used for removing or neutralizing hazardous chemicals and radioactive materials. . DNA can be eliminated by immersing pipette parts in at least 3% (w/v) sodium hypochlorite for at least 15 minutes (2,3). Rinse well with distilled water and allow to . This article is meant to provide guidance and recommendations to ensure optimal and reliable performance of the decontamination process using autoclave steam sterilizers. STERIS Life Sciences technical service specialist, Aaron J Mertens, and Director of Marketing, Marcel Dion, wrote a detailed article that explores why this process is recommended.

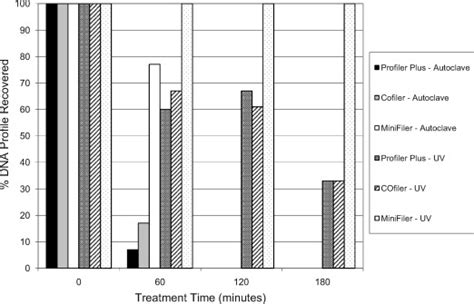

This study was undertaken to determine the best decontamination strategy for the removal of DNA from laboratory consumables. . Autoclaving is more effective than UV irradiation because it can eliminate short fragments of contaminating DNA more effectively. Lengthy autoclave or UV irradiation treatments are required. Depending on bulb power, a . In the USA alone, there are more than 100 commercial autoclave plants for processing infectious waste, ranging in size from 35 to 90 tons per day, employing several sterilizing modalities, such as autoclaving. 1 Employment of effluent decontamination systems (EDS) for the treatment mainly of contaminated liquids also generates thousands of .

Following optimization of the autoclave procedure for DNA decontamination, dried saliva samples containing ∼43 ng of DNA (Table 1) were prepared and subjected to UV irradiation or autoclave treatment for up to 180 min to assess the relative effectiveness of the treatments.

INTRODUCTION. Although the military has been developing decontamination methods for their purposes for decades, 1 research conducted or funded by nondefense government agencies with a focus on the decontamination of civilian facilities had been minimal prior to 2001. That changed following the intentional release of Bacillus anthracis spores .The preparation procedure of AFM imaging in liquid is according to ref. 44.Here is a brief description of the deposition protocol used: 1.0 mM MgCl 2, 25 mM KCl, 10 mM HEPES (pH 7.5) solution was used as deposition buffer, 10 mM NiCl 2, 25 mM KCl, 10 mM HEPES (pH 7.5) solution was used as imaging buffer, NiCl 2 containing buffer only plays a role of increasing .DOI: 10.1016/j.fsigen.2009.06.008 Corpus ID: 20057077; UV irradiation and autoclave treatment for elimination of contaminating DNA from laboratory consumables. @article{Gefrides2010UVIA, title={UV irradiation and autoclave treatment for elimination of contaminating DNA from laboratory consumables.}, author={Lisa A. Gefrides and Mark C Powell and Michael Donley and Roger .

AUTOCLAVE DECONTAMINATION PROCEDURES. . B. Recombinant DNA molecules contained in an organism or in a viral genome shall be shipped under the applicable regulations of the governmental agencies listed above. C. For purposes of the NIH Recombinant DNA Guidelines (Federal Register, Vol. 55, No. 41, Thursday, March 1, 1990, pages 7447-7448): . Nowadays, engineers face challenges in developing novel technologies to find environmental and industrial solutions to address microbial contamination Microbes and treated objects differ significantly in their ability to tolerate the decontamination methods. This work introduces a comprehensive review of recent trends of microbial decontamination for . For dry DNA at 25°C, 5.7×10 −11 SSBs and 3.2×10 −12 DSBs are induced per Gy and Dalton of DNA whereas for DNA in aqueous solution at 25°C, 1.1×10 −7 SSBs and 5.4×10 −9 DSBs are induced . This indicates that hydroxyl radical production is the key factor in the decontamination of DNA in solution.

After the device is clean, it should be sterilized either steam sterilization with an autoclave, or a combination sodium hydroxide and autoclaving, using one of the four following methods: Option 1. Autoclave at 134°C for 18 minutes in a prevacuum sterilizer. Option 2. Autoclave at 132°C for 1 hour in a gravity displacement sterilizer. Option 3. Several studies have evaluated the effectiveness of sterilisation techniques for DNA decontamination, including . 4, 13 Gefrides et al. 4 reported that autoclave decontamination (121 C, 120 min .Decontamination renders an item or material safe to handle. The level of microbial contamination is reduced enough that it can be reasonably assumed free of risk of infection transmission. . For efficient heat transfer, steam must flush the air out of the autoclave chamber. Before using the autoclave, check the drain screen at the bottom of .

achieve decontamination if an autoclave is tightly packed. 5.3.7 Do not autoclave items containing corrosives (e.g. acids, bases, phenol), solvents or volatiles (e.g. ethanol, methanol, chloroform), flammables, or radioactive materials. 5.3.8 Do not mix contaminated (“dirty”) and clean items together during the same autoclave cycle.

DNA and RNA contamination in laboratory settings, we need to think not only about inactivating . Autoclaves are steam sterilizers commonly used in healthcare, but they arechamber before loading the autoclave. c. Place a piece of autoclave tape (Class I Chemical Indicator) on the outside of the container or bag. Black stripes appearing on the tape give a visual verification that the material has been processed. 5 AUTOCLAVE TAPE . d. If an autoclave is available, place the load + its secondary container in the .

UV irradiation and autoclave treatment for elimination of

To prevent risk of shock always disconnect power before removing covers or performing any service procedure.

dna decontamination autoclave|UV irradiation and autoclave treatment for elimination of